Replaced Crankshaft Position Sensor But Still Get Code

Okay, so you’ve been there, right? You get that dreaded check engine light. It’s like a little red beacon of doom, just staring at you from your dashboard. Ugh.

And then, after some digging, or maybe a quick trip to the auto parts store for a scan, you’ve got your culprit. Let’s say, for argument’s sake, it’s the ol’ crankshaft position sensor. You know, the guy that tells your engine’s computer where the crankshaft is so it knows when to spark the cylinders. Super important stuff, really.

So, you’re thinking, “Great! I’ll just swap that thing out and be good to go!” Easy peasy, lemon squeezy, right? You buy the part – maybe even splurge on the OEM one, because you’re feeling fancy and you really want this fixed. You get your hands dirty, or maybe you bribe a friend with pizza to help. You wrestle with that little sensor, probably curse its existence a few times, and finally, poof, it’s in!

You clear the code, feeling like a total car guru. You start the engine. It purrs like a kitten. Victory! You drive around for a bit, feeling smug. Then, BAM! That little red light is back. What the…?!?

Seriously? I just changed that thing! Is this some kind of automotive cruel joke? Did the universe conspire against my wallet and my sanity? It feels that way, doesn't it?

So, what’s going on here? You’ve done the obvious thing, the thing everyone told you to do, and yet, the code persists. It’s like telling a doctor you have a headache and them prescribing aspirin, and then your head still throbbing an hour later. Frustrating is an understatement, my friend.

Let’s dive into why this magical, yet maddening, situation might be happening. Because, spoiler alert, it’s not always the sensor itself that’s the sole villain.

First things first, let’s give a little love to the crankshaft position sensor (CKP) itself. This little guy is a marvel of modern engineering, a tiny but mighty component. It’s usually a magnetic pickup or a Hall effect sensor. It works by detecting the passing teeth of a reluctor wheel (or a notched ring) on the crankshaft. As these teeth pass by, they create a change in the magnetic field, which the sensor picks up. This generates a signal, a series of pulses, that tells the engine control unit (ECU) – your car’s brain – the rotational speed and position of the crankshaft. Without this crucial info, the ECU is flying blind. It doesn’t know when to fire the spark plugs or when to inject fuel. Hence, the check engine light and, often, a no-start condition or rough running.

So, when that code pops up, and it’s pointing to the CKP, it’s a pretty good bet that the sensor is involved. But, and this is a big but, it might not be the only thing involved.

The Part Itself – Is It Really New?

Let’s be real. Sometimes, even brand-new parts can be duds. It’s rare, but it happens. Maybe you got a lemon. Maybe the packaging was damaged, and something internally got rattled. It’s like buying a lottery ticket and expecting to win – it could happen, but it’s not the norm. You’ve gotta consider the possibility, however slim, that the new sensor is… well, not working as intended. It happens to the best of us, or at least, the best of parts manufacturers.

Installation Shenanigans: Did it Really Click?

Okay, fess up. Did you really make sure that new sensor was seated properly? Sometimes, these little guys have a specific connector that needs to snap into place with a satisfying ‘click.’ If it’s not fully seated, or if the wiring harness isn't plugged in securely, you're essentially back to square one. The signal just isn't getting through. It’s like trying to have a conversation with someone who’s got their fingers in their ears. They can’t hear you, and you can’t get your point across. It’s a communication breakdown of epic proportions.

And what about the wiring? That little wire leading to the sensor? It’s not exactly made of titanium, is it? It can get pinched, frayed, or just plain old damaged. Did it get snagged during the installation process? Did you accidentally nick it with a wrench? Even a tiny bit of damage can disrupt the electrical signal. Think of it like a water hose with a small leak. It’s still carrying water, but not as efficiently as it should, and some is getting lost along the way. That lost signal? The ECU sees it as a problem.

The Connector Conundrum: Dirty, Corroded, or Damaged?

The connector is another prime suspect. Over time, these can get a bit grimy. Dirt, oil, moisture – they all love to get cozy in there. And when they do, they create resistance. Resistance is the enemy of a clean electrical signal. It’s like trying to read a book with smudges on every page. You can still read it, but it’s a pain, and some words might get lost. A dirty or corroded connector can cause intermittent signal loss, which the ECU definitely notices. Sometimes, a good cleaning with some electrical contact cleaner can work wonders. Other times, the connector itself might be physically damaged and need to be replaced. Ouch.

Wiring Harness Woes: The Unseen Villain

This is where things can get a little more… detective-y. The wiring harness that leads to the CKP sensor is part of a larger network. And that network can have its own issues. We’re talking about breaks in the wire, short circuits to ground, or shorts to power. These can be caused by anything from vibration over time to rodent damage (yes, those little critters love to chew on wires!). Finding these can be a real pain in the neck, requiring you to trace the wiring all the way from the sensor to the ECU, or at least to the next junction box. It’s like following a breadcrumb trail, but instead of delicious pastries, you’re looking for a tiny electrical fault.

The Reluctor Wheel: The Other Half of the Equation

Remember that reluctor wheel we talked about? The one with the teeth that the CKP sensor reads? Well, that wheel is attached to the crankshaft. What if it’s the problem? It’s possible for the teeth on the reluctor wheel to become damaged, bent, or even broken. This would give the CKP sensor a wonky signal, or no signal at all, even if the sensor itself is perfectly fine. Think of it like trying to use a comb with missing teeth. It’s not going to comb your hair very effectively, is it? Damage to the reluctor wheel usually means a more involved repair, potentially involving removing the crankshaft pulley or even more.

The Flywheel/Flexplate Factor: Another Toothy Issue

In some vehicles, the crankshaft position sensor actually reads teeth on the flywheel (for manual transmissions) or the flexplate (for automatic transmissions) instead of a separate reluctor wheel. So, if those teeth are damaged, chipped, or missing, you’re going to have the same signal issues. This is another one that requires a bit more disassembly to inspect. It’s like finding out the problem wasn't with the scanner, but with the actual thing you were trying to scan!

The ECU Itself: The Brain’s Meltdown?

Now, this is the big kahuna, the last resort, the “Oh no, this is gonna be expensive” scenario. It’s possible for the engine control unit (ECU) to have an internal fault that makes it misinterpret signals, or fail to properly process the signal from a perfectly good CKP sensor. This is, thankfully, pretty rare. ECUs are built to be robust. But when all else fails, and you’ve checked everything else, it’s a possibility. This is where you really want to be sure before you start replacing the car’s brain. It’s like going to the doctor for a headache and them saying, “Yep, your brain’s broken.” You’d want a second opinion, right?

What to Do Next? The Detective Work Begins!

So, you’ve replaced the sensor, cleared the code, and it’s back. Don’t despair! It’s time to put on your detective hat. Here’s a little game plan:

1. Double-Check the Basics:

- Confirm the part number was correct for your vehicle. Sometimes, online listings can be a little… vague.

- Make sure the connector is snapped in all the way. Give it a good tug. Does it feel secure?

- Inspect the wiring harness leading to the sensor. Any nicks, cuts, or signs of rodent damage?

2. Dig Deeper into the Codes:

- Are there other codes present? Sometimes, a CKP sensor code is a symptom of a different, underlying issue. For example, a problem with the camshaft position sensor can sometimes throw related codes.

- Is the code specific? Does it say “CKP circuit malfunction” or “CKP signal erratic”? The wording can give you clues.

3. Test the Signal (If You’re Feeling Brave):

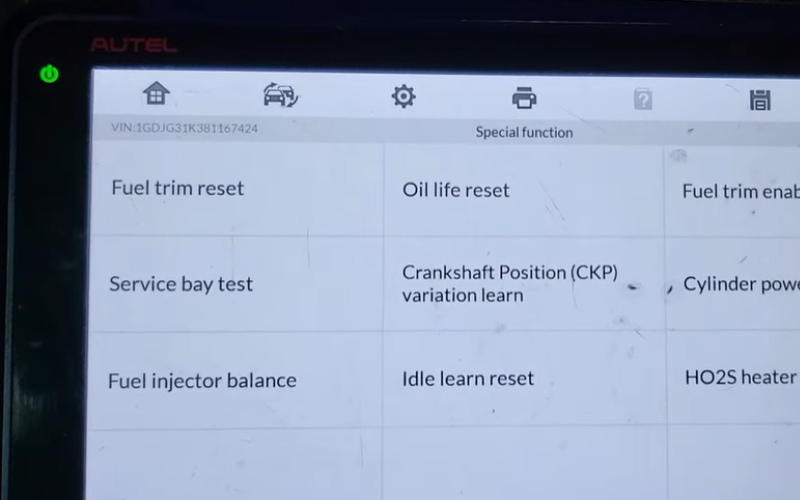

This is where things get a bit more technical. You can use a multimeter to check for voltage at the sensor connector when the engine is cranking. You can also sometimes use an oscilloscope to check the waveform of the CKP signal. If you’re not comfortable with this, it’s definitely time to call in the cavalry. Your local mechanic has the tools and the know-how.

4. Consider the Reluctor Wheel/Flexplate:

If all the electrical checks out, and you’re still getting the code, the next step is to investigate the reluctor wheel or flexplate. This usually involves removing the crankshaft pulley and using a borescope or other inspection tools to look at the teeth. It's not a weekend DIY job for everyone, let’s just say that.

5. Professional Help is Your Friend:

Sometimes, you just have to admit defeat and call in the pros. A good mechanic has seen this before. They have the diagnostic tools and the experience to quickly pinpoint the real issue. It might cost you a bit more upfront, but it can save you a lot of time, frustration, and potentially replacing parts you don’t need to.

Replacing the crankshaft position sensor is often the right first step, but it’s not a magic bullet. It’s like going to the doctor and them giving you a prescription for one thing, but the actual problem is a little more complicated. Don’t get discouraged! With a bit of patience and some good old-fashioned detective work, you’ll get to the bottom of it. And then, you can finally enjoy that sweet, sweet feeling of a check-engine-light-free dashboard. Ah, bliss!