Place The Steps For Statistical Process Control In Order

Ever feel like you're juggling flaming torches while riding a unicycle? Life can sometimes feel that way, right? Things are constantly moving, and we're trying our best to keep them from falling apart. Well, what if I told you there's a way to make all that juggling a little less… fiery? It's called Statistical Process Control, or SPC for short. Sounds a bit technical, I know, but stick with me. It's actually a super handy way of making sure things run smoothly, not just in fancy factories, but in pretty much anything we do!

Think of it like this: imagine you're baking your famous chocolate chip cookies. You've got your recipe, your trusty oven, and a mountain of chocolate chips. You want those cookies to be perfect every single time – chewy in the middle, slightly crisp on the edges, and bursting with chocolatey goodness. SPC is basically a detective for your cookie-baking process.

So, how does this detective work? It's all about understanding variation. In the cookie world, variation is all the little differences that can happen. Maybe one batch of flour is a little drier, or your oven temperature fluctuates by a few degrees. These tiny changes are normal, like the little wobbles on your unicycle. SPC helps us tell the difference between the normal wobbles and a wobble that's about to send you face-first into the cookie dough.

Let's break down the "steps" of this detective work. They're not really steps in a rigid, military march kind of way. More like a series of "hey, let's check this out" moments.

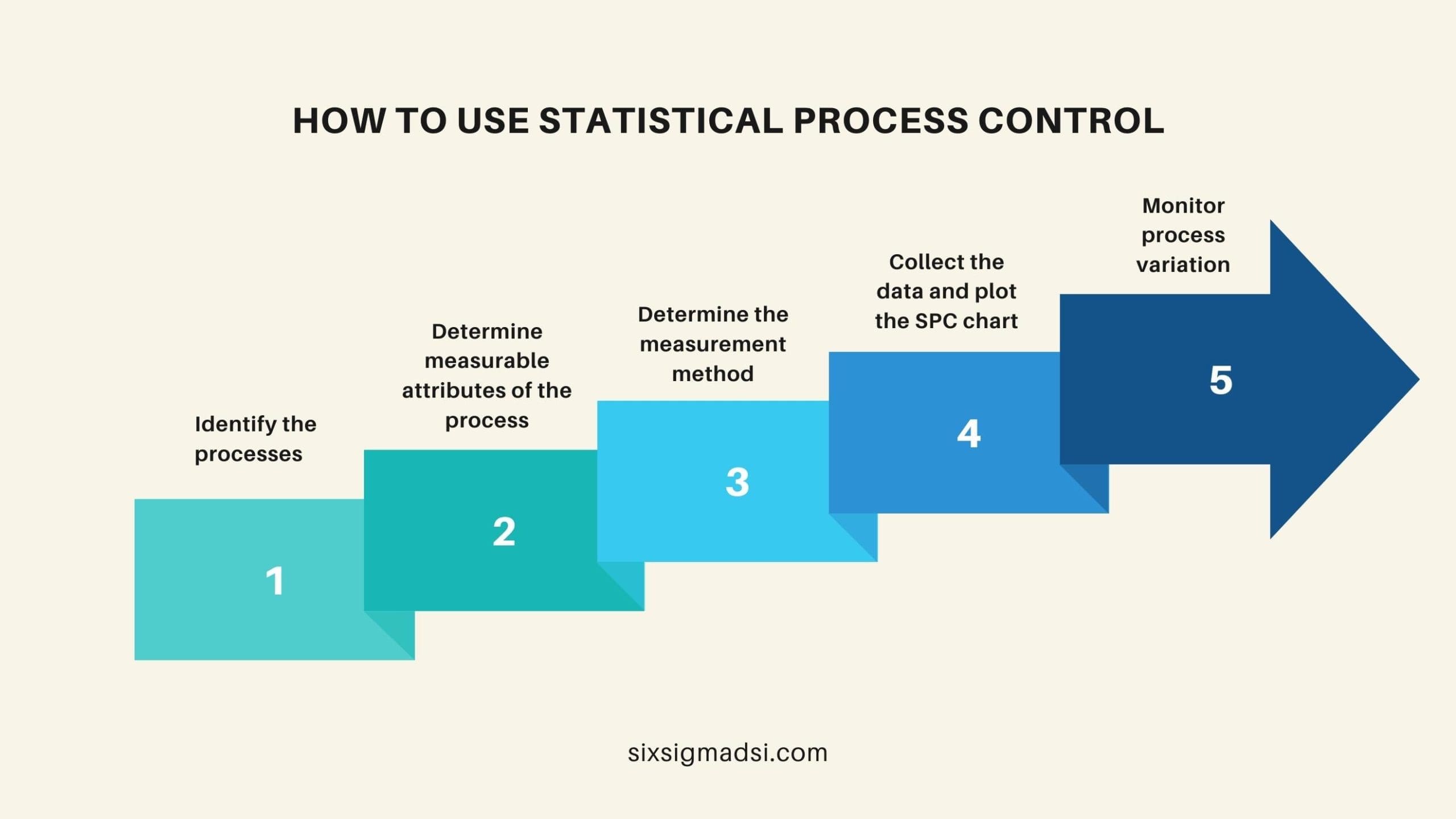

Step 1: What Are We Trying to Do? (Defining the Goal)

First off, we need to be clear about what "good" looks like. For our cookies, it's that perfect texture and taste. In a factory making car parts, it might be a specific diameter or strength. In your morning routine, it could be leaving the house on time without forgetting your keys (a noble goal, indeed!). This is about setting your target, your North Star.

Without knowing what we're aiming for, how can we know if we're hitting the mark? It's like trying to win a game of darts when you don't know where the board is. We need a clear picture of our desired outcome. So, the first step is simply to clearly define what success looks like for whatever you're trying to achieve.

Step 2: How Do We Measure It? (Gathering Data)

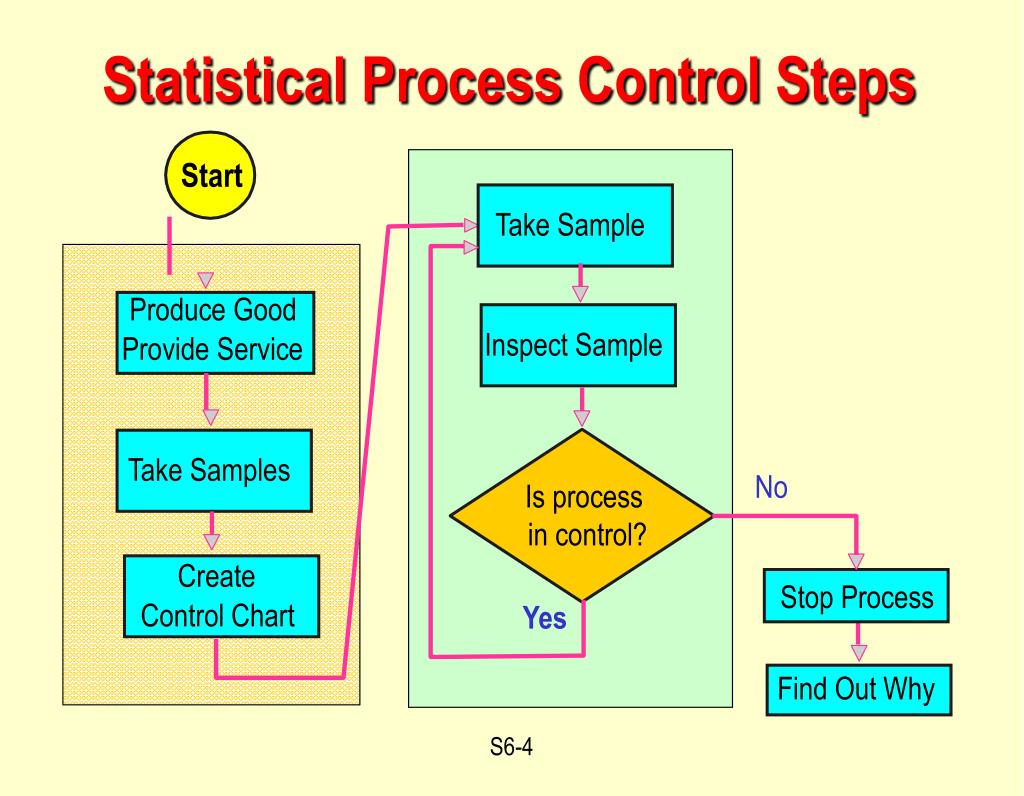

Now that we know what we want, we need to start collecting information. This is where our detective puts on their magnifying glass. For the cookies, it could be weighing the dough for each cookie, timing how long they bake, or even tasting them (the best part!). For the car parts, it's using precise instruments to measure their dimensions. For your morning routine, it might be noting down the time you leave the house each day for a week.

The key here is to gather consistent and reliable data. Think of it like taking notes. If your notes are messy or you miss key details, your detective work will be a bit… fuzzy. So, we're looking for objective measurements. This isn't about guessing; it's about actually observing and recording.

Imagine you're trying to improve your gardening. You want your tomatoes to grow bigger and juicier. You'd start measuring the size of your tomatoes, how much water you give them, how much sunlight they get. That's gathering data! It’s like keeping a garden diary.

Step 3: What Does the Data Tell Us? (Analyzing the Data)

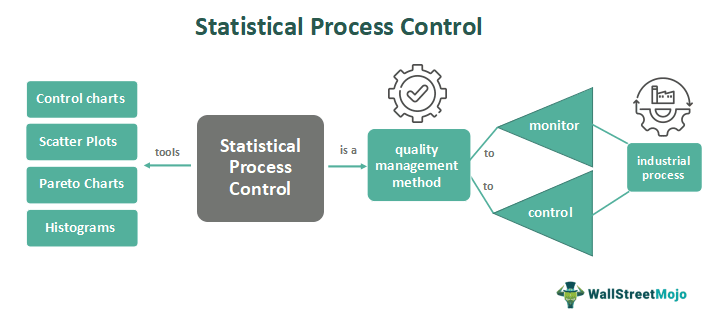

Once we have our notes, our detective starts looking for patterns. This is where the "statistical" part comes in, but don't let that scare you! It's not about complex math equations for everyday use. It's about looking for trends and figuring out what's normal and what's a little… out of the ordinary.

We often use something called a control chart. Think of it as a graph that shows your data over time. It has a middle line (the average, or what you expect), and then two lines above and below it. These are called "control limits." If your data points are happily dancing around the middle line, you're doing great! If a point suddenly jumps way above or below, or if you see a bunch of points consistently going in one direction, that's your detective alarm going off.

Let's go back to the cookies. If your control chart shows that the baking time is creeping up batch after batch, you know something's changing. Maybe your oven is starting to run hotter. Or, if the weight of your cookie dough is getting lighter, you might need to adjust your measuring cup.

It’s like watching your favorite TV show. You know the characters, you know the usual plot twists. When something drastically different happens, you sit up and pay attention. SPC helps us spot those "plot twists" in our processes.

Step 4: Is It Working as Planned? (Identifying Causes)

When our detective alarm goes off, it's time to investigate! Why did that cookie dough get lighter? Did someone use a different scoop? Did the flour bag feel lighter than usual? This is about finding the root cause of the variation. It's not about blaming anyone, but about understanding what happened.

In a more serious setting, if a car part is too big, we'd check the machinery that makes it. Is it calibrated correctly? Is the material consistent? The goal is to understand the "why" behind the deviation.

Think about when your internet connection keeps dropping. You don't just sigh and accept it. You troubleshoot! You check the router, you restart it, you might even call your internet provider. You're trying to find the cause of the problem so you can fix it. That's a real-life SPC investigation!

Step 5: Let's Make it Better! (Taking Action)

Once we know what's causing the problem, we can fix it! This is the "control" part of SPC. We make adjustments to get the process back on track.

For the cookies, if the oven is running hot, you might adjust the thermostat. If your morning routine is consistently making you late, you might decide to set your alarm 15 minutes earlier or lay out your clothes the night before. It's about implementing solutions.

This step is all about making improvements and preventing the same problem from popping up again. It’s like putting a little sign on your oven that says, "Hey, I run a bit hot!" or putting a reminder on your phone to check your measuring cup for cookies.

Step 6: Keep an Eye on Things (Monitoring and Continuous Improvement)

SPC isn't a one-and-done deal. It's an ongoing conversation with your process. We keep collecting data, keep monitoring our control charts, and keep looking for ways to make things even better. It's a cycle of learning and improving.

This is the part where you become a master juggler. You've learned how to anticipate the wobbles, how to adjust your grip, and how to keep those flaming torches (or delicious cookies, or on-time departures) safely in the air.

Why should you care about all this? Because it’s about reducing frustration! It's about getting more of what you want and less of what you don't. Whether it's a perfectly baked cake, a smooth commute, or a project at work that goes off without a hitch, SPC is the quiet helper that makes it all happen. It helps us move from a chaotic "hope for the best" approach to a more thoughtful and reliable way of doing things. So, the next time you’re trying to get something right, remember our friendly SPC detective. It’s just a helpful way to keep things running smoothly, one data point at a time!