Inbound Logistics Include Which Of The Following

Ever found yourself wondering what magic happens before that shiny new gadget or delicious snack lands in your hands at the store? It’s like a secret backstage pass to the world of stuff, and today, we’re peeking behind the curtain to talk about inbound logistics. Sounds a bit fancy, right? But honestly, it's just the cool stuff that happens when goods start their journey to a business, rather than from it. Think of it as the grocery run your favorite restaurant makes, or the package delivery you receive before you can even dream of sending something out yourself.

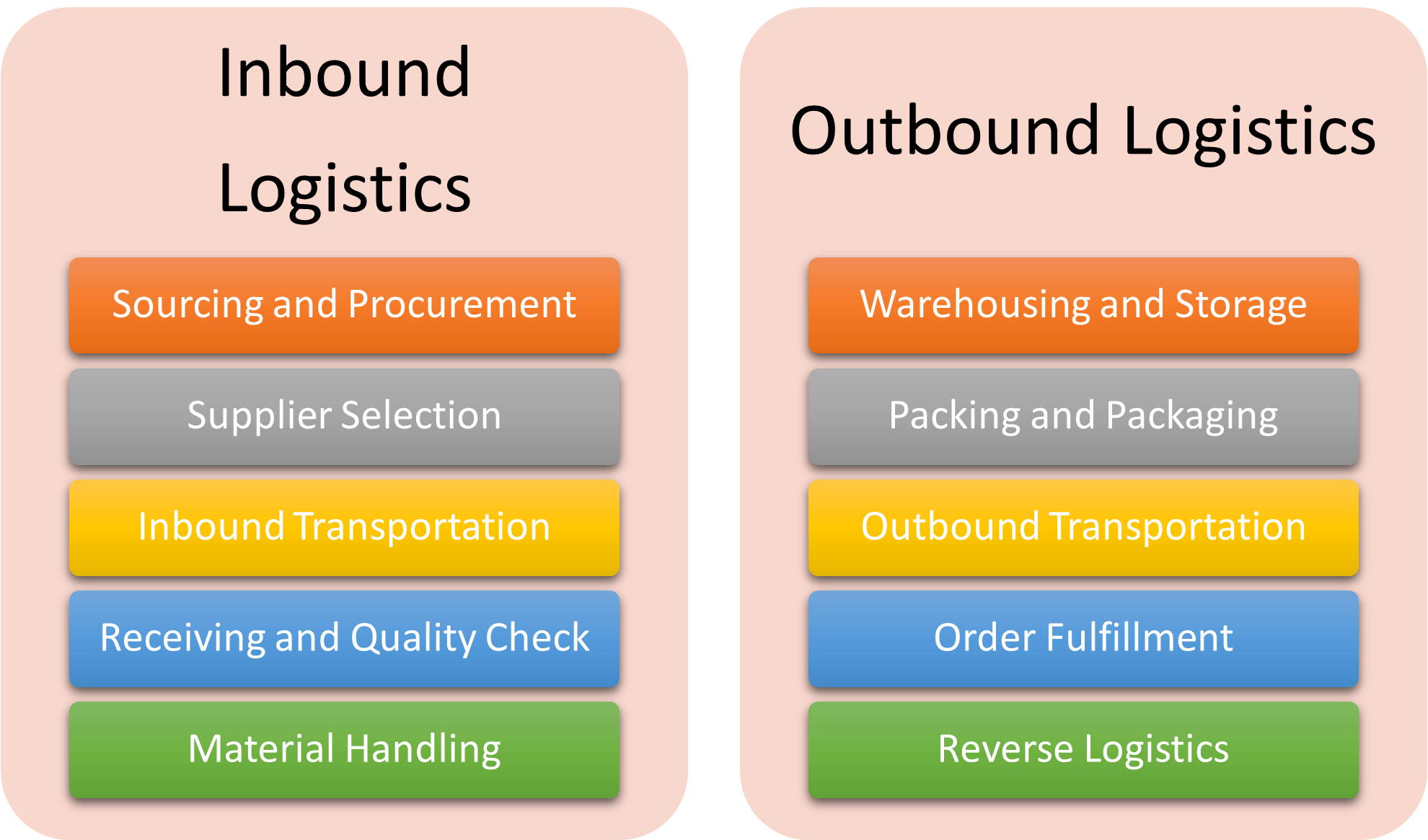

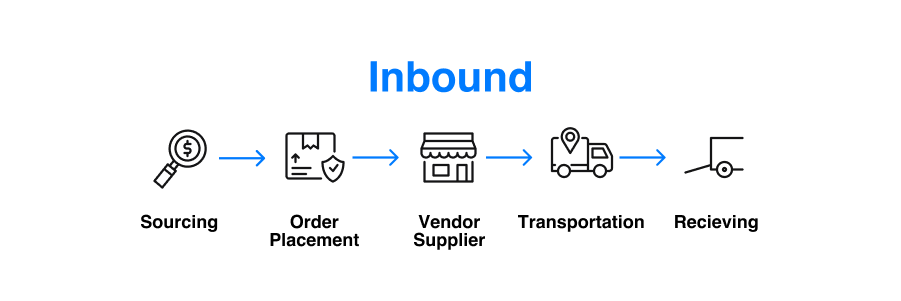

So, what exactly falls under this umbrella of inbound logistics? It’s a whole bunch of things working together, like a well-oiled machine, to make sure that whatever a company needs – be it raw materials for making things, finished products to sell, or even just the office supplies that keep the lights on – actually shows up. We're talking about everything from the moment a purchase order is placed, all the way until those items are neatly tucked away in a warehouse, ready for their next adventure.

The "Getting Stuff In" Party

Let’s break it down a little. When we talk about inbound logistics, we’re really looking at the entire process of how a business acquires and receives goods. It's the stuff that makes sure your local coffee shop has enough beans to brew your morning latte, or that the toy store is stocked up for the holidays. Pretty essential, wouldn't you say?

It's not just about a truck showing up, though. Oh no, it's way more intricate and, dare I say, fascinating!

Purchasing and Procurement: The "I Want This!" Stage

This is where it all begins, right? A business figures out what it needs. It’s like you deciding you absolutely need that new book or that cool plant for your living room. Except, instead of you, it’s a whole company strategizing about what ingredients, parts, or products will make them successful. This involves understanding demand, finding reliable suppliers, and negotiating prices. Think of it as the ultimate shopping list creation, but with big bucks and long-term relationships involved.

When a company decides to buy something, they issue a purchase order (PO). This is basically a formal "yes, please!" to a supplier. It’s a crucial document that outlines exactly what’s being bought, how much, at what price, and when it’s expected. Without a solid PO, things can get messy, fast. Imagine trying to build IKEA furniture without the instructions – chaos!

Inventory Management: The "Where Should We Put This?" Puzzle

Once the goods are on their way, a company needs to be ready to receive them. This is where inventory management comes in. It’s all about keeping track of what you have, where it is, and how much of it you need. Too much inventory, and you’re paying for space and risking things going stale or becoming obsolete. Too little, and you might miss out on sales because you can't fulfill orders. It’s a delicate balancing act, a bit like juggling flaming torches while riding a unicycle – exciting, but requires precision!

This includes everything from deciding how much stock to keep on hand to implementing systems that track items as they move in and out. It’s the digital brain that tells a warehouse manager, "Hey, we’ve got 50 boxes of those widgets arriving tomorrow, and we have space for them right here."

Transportation and Shipping: The "How Do We Get It Here?" Voyage

This is probably the part that most people visualize when they think of logistics. It’s the actual movement of goods. For inbound logistics, it means getting products from the supplier to the business. This can involve a whole spectrum of options:

- Trucks: The workhorses of short-to-medium distance transport. From local deliveries to cross-country hauls, trucks get a lot of stuff moving.

- Trains: Great for bulk goods and long distances. Think of them as the slow-and-steady champions, perfect for moving massive amounts of raw materials.

- Ships: The giants of international trade. If you’ve ever bought something that says "Made in [faraway country]," it probably traveled by sea. They carry oceans of goods!

- Airplanes: For when speed is king. If you need something yesterday, and price is less of a concern, air cargo is your best bet. It’s the express lane of the shipping world.

The choice of transportation depends on factors like cost, urgency, the type of goods, and the distance. It's a complex puzzle where the cheapest option isn't always the best if it means missing a crucial deadline. It’s like choosing between taking a scenic bike ride or a rocket ship to get to your friend’s house – depends on how much time you have!

Receiving and Warehousing: The "Welcome Home!" Moment

So, the truck pulls up, the containers are opened, and the goods are finally here! This is the receiving part. It's not just about unloading; it involves checking the shipment against the purchase order to make sure everything is correct, undamaged, and accounted for. This is the critical quality control step. Imagine ordering a pizza and getting a salad instead – definitely not what you wanted!

Once checked, the items need a place to live. This is where warehousing comes in. Warehouses are more than just big empty buildings; they are strategically designed spaces for storing and managing inventory. They can be massive operations with sophisticated racking systems, automated forklifts, and advanced software to track every single item. It’s the organized chaos of a well-run pantry, just on a much, much grander scale.

Within warehousing, you’ve got different types of storage, like:

- Bulk storage: For large quantities of identical items.

- Pallet storage: Items stacked on pallets, common in many industries.

- Climate-controlled storage: For sensitive goods like food or pharmaceuticals that need specific temperatures.

Material Handling: The "Let's Move This Stuff Around" Choreography

Once things are in the warehouse, they don’t just magically arrange themselves. Material handling is the process of moving, protecting, storing, and controlling materials and products throughout manufacturing, warehousing, distribution, consumption, and disposal. Inbound logistics focuses on the "storing" and "moving" within the receiving and warehousing phases.

This involves a whole arsenal of equipment: forklifts, pallet jacks, conveyor belts, cranes, and even robotic arms! It’s a carefully choreographed dance of machinery and people, all working to ensure goods are moved efficiently and safely from the receiving dock to their designated storage spots. Think of it as the ultimate game of Tetris, but with real-life boxes and serious consequences if you drop them!

Information Flow and Technology: The "Behind the Scenes" Brainpower

While we’re talking about physical goods, none of this would happen smoothly without a constant flow of information. This is where technology shines! Enterprise Resource Planning (ERP) systems, Warehouse Management Systems (WMS), and Transportation Management Systems (TMS) are the digital nervous systems that keep everything connected.

These systems track inventory levels, manage purchase orders, schedule shipments, monitor delivery status, and provide crucial data for decision-making. They are the silent heroes, the invisible threads that tie the entire inbound logistics process together. Without them, it would be like trying to navigate a city without a map or GPS – lots of getting lost and frustration!

Why Is This All So Cool?

So, why should you care about all this behind-the-scenes action? Because inbound logistics is the silent engine that drives modern commerce. It’s what allows businesses to have the products you want, when you want them. It's the reason why you can order something online and have it show up at your door, or why your favorite restaurant always seems to have the ingredients for that amazing dish.

When inbound logistics is done well, it leads to lower costs for businesses, which often translates to better prices for us, the consumers. It means less waste, more efficiency, and a smoother overall experience for everyone involved. It’s a testament to human ingenuity and the power of organization.

Next time you pick up a product, take a moment to appreciate the incredible journey it took to get there. From the initial order placed by the company, through its transportation and careful handling, all the way to its place on the shelf or in the warehouse – it’s all part of the fascinating world of inbound logistics. Pretty neat, huh?