In Terms Of Facility Design What Is Throughput

Ever found yourself stuck in a particularly sluggish queue, staring longingly at the seemingly endless line ahead, and thought, "Is this place even trying to get people through?" Yeah, me too. That feeling, that collective sigh of exasperation as the person at the front fumbles with their change like they're defusing a bomb, that’s the opposite of good throughput. And in the world of facility design, throughput is basically the VIP pass to getting things done efficiently. Think of it as the facility’s gotta-go-fast score.

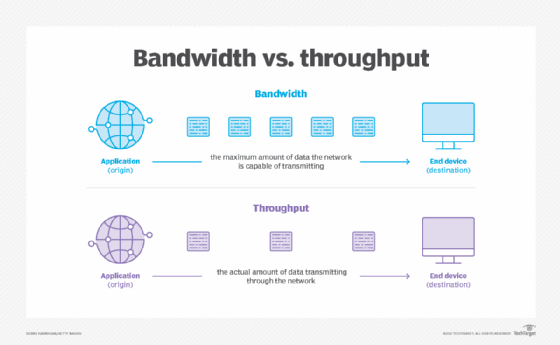

So, what exactly is throughput when we’re talking about designing places where stuff (or people!) needs to move? In the simplest, most non-jargon-y way possible, it’s about how much stuff can get processed or moved through a system in a given amount of time. It’s the rate at which things go from "here" to "there" without getting gummed up like a clogged drain after a spaghetti dinner.

Imagine your favorite fast-food joint. If the order-taker is super slow, the kitchen is a chaotic mess, and the person bagging the food is juggling burgers like a circus act gone wrong, your throughput is going to be dismal. You’ll be watching tumbleweeds blow through the parking lot while you’re still waiting for your lukewarm fries. But if they have a well-oiled machine – a speedy order system, an efficient kitchen layout, and a swift hand-off at the pickup counter – bam! You’re out the door with your delicious, hot food in no time. That’s good throughput in action, and it’s a beautiful, beautiful thing.

This isn’t just about burger joints, though. It applies to everything from a busy hospital emergency room to a massive Amazon warehouse, even to the flow of information in your office. If the goal is to get things done, throughput is the name of the game. It’s the silent superhero of operational efficiency, the unsung hero that makes our lives a little bit easier (or at least, a little bit less frustrating).

The 'Ugh, This is Going to Take Forever' Factor

Let’s dive a bit deeper into what makes throughput good or, shall we say, aggressively mediocre. In facility design, throughput is all about the physical space and how it facilitates movement. Think about it like designing a highway. If you have too many lanes merging into one at a crucial point, you’re going to have a traffic jam of epic proportions. Drivers will be honking, tempers will flare, and the whole system grinds to a halt. That bottleneck is the enemy of throughput.

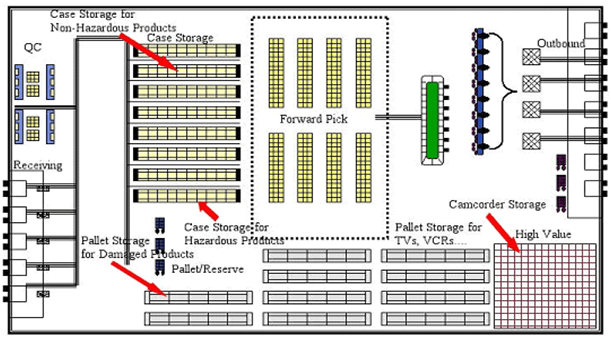

In a warehouse, a bottleneck might be a narrow aisle where forklifts constantly bump into each other, or a loading dock that’s too small for multiple trucks to unload simultaneously. In a hospital, it could be a cramped triage area or a shortage of exam rooms, leading to patients stacking up like firewood. It’s the spot where things get stuck, where the flow of goods or people dramatically slows down. And when things slow down, costs go up, stress levels skyrocket, and customer satisfaction plummets faster than a dropped ice cream cone on a hot day.

So, a good facility designer is basically a traffic engineer for physical spaces. They’re looking at the layout, the equipment, the workflow, and asking, "Where are things likely to get stuck? How can we prevent that? How can we make this as smooth and as fast as possible without sacrificing safety or quality?" It’s like planning a marathon – you need clear paths, plenty of water stations, and a finish line that doesn't get mobbed by overzealous spectators.

When the Conveyor Belt of Life Gets Jammed

You've probably experienced a low-throughput situation without even realizing it. Think about going through airport security. If the scanners are slow, the bag inspection area is cluttered, and there aren't enough agents to direct people, the line snakes back into the check-in area. You start to feel that familiar dread creep in. You’re this close to your gate, but you might as well be hiking the Appalachian Trail based on how long it’s taking to get to the other side.

On the flip side, remember that one airport where security was a breeze? Agents were everywhere, people were being guided smoothly, and the whole process felt almost… pleasant? That’s high throughput. The facility was designed to maximize the flow of people, minimizing those frustrating delays. They’ve thought about the number of security lanes, the spacing between them, the layout of the waiting area, and the efficiency of their scanning equipment.

It’s the same principle for a manufacturing plant. If the machines aren't positioned correctly, if materials aren’t delivered to the right spot at the right time, or if finished goods aren't moved away quickly enough, the whole production line can seize up. It's like trying to make a giant sandwich, but the bread is on the other side of the room, the fillings are in the basement, and you only have one tiny knife. You're going to spend more time fetching and carrying than actually assembling the deliciousness. And nobody wants a sad, half-assembled sandwich.

Beyond the Speed: The 'How Much?' Part

Throughput isn't just about speed, though. It's also about volume. How many cars can get through that toll booth per hour? How many packages can a fulfillment center ship in a day? How many patients can a clinic see in a week?

Think of it like a party. If you only have one tiny appetizer tray and a hundred guests, the throughput of appetizers will be incredibly low. Everyone’s going to be fighting over the last mini quiche, and the party will feel… lacking. But if you have multiple stations with different snacks, strategically placed, the guests can circulate, grab what they need, and everyone gets a taste. That’s higher throughput of deliciousness!

In facility design, this means having enough resources – enough machinery, enough staff, enough space – to handle the expected demand. If a factory is designed to produce 1,000 widgets a day but suddenly gets an order for 5,000, their throughput is going to be a major problem. They’ll be running machines overtime, pushing their staff to the brink, and probably missing deadlines. A well-designed facility anticipates these fluctuations and has the capacity to handle them.

It’s about finding that sweet spot where you can process a significant amount of stuff (or people, or information) without everything becoming a chaotic mess. It’s the difference between a well-organized buffet with plenty of food and a frantic scrum around a single, half-empty chafing dish.

The 'Smooth Sailing' Syndrome

When a facility has good throughput, it feels almost effortless. Things just… happen. Products move from raw materials to finished goods without undue delay. Patients are seen, treated, and discharged efficiently. Information flows seamlessly between departments. It’s the feeling of being on a well-oiled merry-go-round – you’re moving, but it’s controlled, predictable, and not at all nauseating.

Consider a supermarket. A well-designed supermarket has wide aisles, clear signage, and checkout counters that are always adequately staffed during peak hours. You can get your groceries, zip through the checkout, and be back home before your ice cream starts to melt. That’s high throughput. The design facilitates your ability to acquire goods and exit the facility quickly and painlessly.

Conversely, a supermarket with narrow, cramped aisles, overflowing shelves that block pathways, and only two checkout lanes open during the Saturday rush? That’s a recipe for low throughput and maximum frustration. You’ll be dodging other shoppers, wrestling with your cart, and feeling like you’re in a never-ending maze. And all you wanted was milk and bread!

Why Should I Care About This 'Throughput' Thing?

You might be thinking, "Okay, I get it. Things should move fast. So what?" Well, you should care because good throughput directly impacts your wallet, your time, and your sanity. For businesses, higher throughput means:

- Increased Profitability: More stuff processed means more sales. It's simple economics. Think of it as a cash register that rings more often.

- Reduced Costs: When things move efficiently, you waste less time, less labor, and fewer resources. Less downtime, fewer errors, and less need for frantic fire-fighting.

- Improved Customer Satisfaction: Nobody likes waiting. When you get what you need quickly and easily, you’re a happy customer. Happy customers come back.

- Better Resource Utilization: Your machines, your staff, and your physical space are being used to their full potential, not sitting idle or being overwhelmed.

For you, the end-user, good throughput means:

- Less Waiting: This is the big one, right? Less time stuck in lines, less time waiting for service.

- More Convenience: Things just work better. It’s a smoother, more pleasant experience.

- Faster Service: Whether it’s getting your order, your medical treatment, or your package, faster is generally better.

Think about the difference between ordering an item online from a company with a slick, efficient fulfillment operation versus one where your order gets lost in the shuffle, shipped late, and arrives looking like it went through a wrestling match. The one with good throughput is going to get your business again. The other? Well, let’s just say you’ll be clicking on a competitor’s link next time.

The Designer's Dilemma: Balancing Speed and Sanity

Designing for throughput isn't just about jamming as many things as possible into a space as quickly as possible. It's a delicate dance. You need to balance speed with safety, efficiency with quality, and capacity with flexibility. You don’t want a factory floor so packed with machinery that there’s no room for maintenance, or a hospital where patients are wheeled down hallways like cars in a demolition derby.

It’s about smart layout, thoughtful process design, and using technology effectively. It’s about understanding the flow of your specific operation and proactively removing potential roadblocks. It’s like planning a road trip: you don’t just pick random destinations; you map out the route, anticipate traffic, and make sure you have enough gas in the tank. You’re optimizing the journey.

So, the next time you’re breezing through a store, or getting your coffee in record time, or seeing your doctor without an agonizing wait, take a moment to appreciate the unsung hero: throughput. The facility designer who thought about how to make your experience less like a root canal and more like a smooth ride on a water slide. They're the real MVPs of our modern, fast-paced world, making sure the conveyor belt of life keeps moving, one efficient step at a time.