An Operations Strategy For Inventory Management Should Work Toward

You know that feeling? The one where you’re rummaging through your pantry, convinced you have exactly three cans of black beans for that chili recipe, only to unearth a dusty, half-eaten jar of pickled beets from Aunt Mildred’s visit last Thanksgiving? Yeah, that’s inventory management gone rogue. And trust me, we’ve all been there. Whether it's your personal spice rack or a sprawling warehouse, the goal of a good operations strategy for inventory management is pretty simple, really. It’s about making sure you have the right stuff, in the right place, at the right time, without drowning in a sea of "stuff" you don't need.

Think of it like your wardrobe. You wouldn't want to be caught in July without a decent pair of shorts, right? Or, conversely, have ten identical pairs of cargo shorts from 2008 taking up prime real estate. A smart wardrobe strategy means having your go-to jeans readily available for that spontaneous casual Friday, knowing where your favorite, slightly-worn-in band t-shirt is for those Netflix nights, and, crucially, not having that sequined disco shirt from your college phase collecting dust in the back, unless you’re planning a very specific, retro-themed party.

In the business world, this is exactly what we're aiming for with inventory. We don’t want to be caught short when a customer suddenly decides they need that widget, just like you don’t want to discover you’re out of coffee beans at 7 AM on a Monday. Equally, we don’t want to be sitting on mountains of those widgets, slowly depreciating like a forgotten avocado at the bottom of the fruit bowl, while we’re paying for the storage space. It’s a delicate dance, a balancing act that requires a bit of foresight, a dash of common sense, and a willingness to occasionally admit that yes, you probably have too many novelty mugs.

The Elusive "Just Enough"

The holy grail of inventory management is, of course, the mythical "just enough." It's like finding that perfect parking spot right outside the grocery store on a Saturday afternoon – seems impossible, but when it happens, you feel like a rockstar. In business terms, "just enough" means having enough stock to meet demand, satisfy your customers, and keep operations humming along smoothly, but not so much that you’re essentially running a glorified storage locker for things that might eventually be useful.

Imagine you run a small bakery. You love baking those fancy, multi-tiered cakes. You order enough premium vanilla beans to last a year, just in case. Then, suddenly, everyone wants cupcakes. Your premium vanilla beans are still sitting there, perfectly preserved, but you’re scrambling to get more flour and sugar. That’s a classic inventory miscalculation. A good strategy would have anticipated that cupcake craze, or at least had a system to pivot quickly. It’s about flexibility, folks. Like knowing how to swap out your gym shorts for, you know, actual pants when the occasion calls for it.

This also ties into the idea of minimizing waste. Think about food. How many of us have opened the fridge to find sad, wilting lettuce or a yogurt that’s well past its prime? That’s money literally going into the bin. In business, it’s the same principle. Obsolete stock, expired goods, items that have gone out of fashion – these are all forms of inventory waste. An effective strategy works to prevent that. It’s about being mindful of what you’re holding onto and for how long.

Knowing Your Stuff (Literally)

One of the biggest hurdles is simply knowing what you’ve got. This sounds obvious, right? But in a busy environment, things can get lost, misplaced, or miscounted. It’s like when you're packing for a trip and you swear you put your toothbrush in your toiletry bag, only to find it later nestled amongst your socks. It’s that moment of frantic searching, that nagging doubt, that we want to eliminate from the business equation.

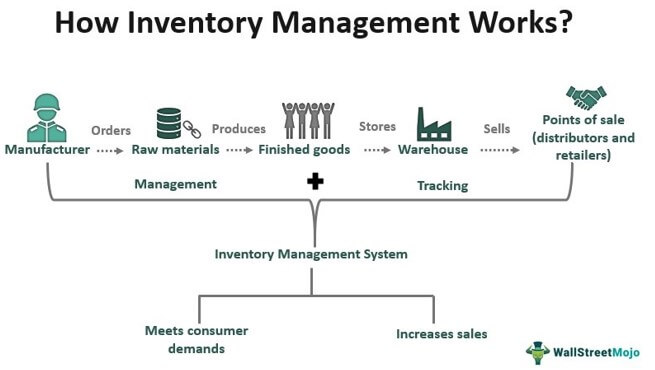

Modern inventory management systems are like having a super-powered, incredibly organized personal assistant for your stock. They can track everything, from the moment an item enters your doors to the moment it leaves. This means knowing exactly how many of Product X you have, where it’s located, and when you last sold one. It’s like having a digital inventory of your entire house, where you can instantly locate your favorite spatula or that one specific screwdriver you only ever need for that one stubborn screw.

This level of visibility is absolutely crucial. Without it, you’re essentially flying blind. You might order more of something you already have in abundance, or worse, run out of something critical because you thought you had more than you actually did. It's like trying to bake a cake without checking if you have eggs. You get halfway through the recipe, realize your crucial mistake, and then have to embark on a frantic, last-minute egg run. Not exactly the zen experience of baking, is it?

The Art of Forecasting (Without a Crystal Ball)

Now, predicting the future is a tricky business. Even those weather apps can’t always get it right, and they’re dealing with clouds and precipitation, not the capricious whims of consumer demand. But a good inventory strategy involves some form of forecasting. It’s not about having a crystal ball, but about using data, past trends, and a bit of informed guesswork to anticipate what you’ll need.

Think about seasonal items. You know, like Halloween costumes. You wouldn't expect to sell many of those in July, would you? But in October? Oh boy, watch out! A smart retailer will ramp up their costume inventory as Halloween approaches. Similarly, if you sell ice cream, you’ll probably stock up more in the summer than in the dead of winter. It's about recognizing patterns and planning accordingly. It's like knowing that your favorite sweater is going to be essential for that December holiday party, so you make sure it's clean and readily accessible, not buried under winter coats you haven’t touched in years.

This forecasting isn’t just about the big picture, either. It’s about understanding the nuances. For example, if you sell two types of coffee, a dark roast and a light roast, and you notice that your dark roast sales spike whenever the weather gets colder, that’s valuable information. Your inventory strategy should reflect that. It's like knowing that your friend always orders fries when they get a burger, so you proactively suggest adding fries to their order. You're not psychic, you're just paying attention!

Balancing the Books (and the Shelves)

The ultimate aim is to achieve a healthy balance. Too much inventory ties up capital that could be used elsewhere – maybe for marketing, innovation, or even giving your employees a much-needed pizza party. Too little, and you risk losing sales, disappointing customers, and damaging your reputation. It's like having too many socks and not enough underwear. Both are important, but one imbalance can lead to some awkward situations.

A well-executed operations strategy for inventory management is about finding that sweet spot. It’s about making smart decisions that allow you to be responsive to customer needs without being burdened by excess stock. It’s about efficiency, not just for the sake of it, but because it directly impacts your bottom line and your ability to thrive.

Consider the concept of Just-In-Time (JIT) inventory. This is a philosophy where materials are received from suppliers only as they are needed in the production process. It's like ordering ingredients for dinner just before you start cooking, rather than having a pantry overflowing with things that might spoil. JIT can significantly reduce holding costs and minimize waste. However, it also requires a highly reliable supply chain. If your broccoli supplier has a truck breakdown, your dinner plans (and your JIT strategy) can go out the window. It's a bit like relying on a friend to bring snacks to a party – usually works, but there’s always that one time they forget.

Keeping Things Moving Smoothly

Ultimately, an operations strategy for inventory management should work toward making everything flow. Think of a river. It’s constantly moving, replenishing, and adapting. It doesn’t get stagnant and full of debris (well, ideally). In business, this means having a smooth flow of goods from suppliers, through your operations, and out to your customers.

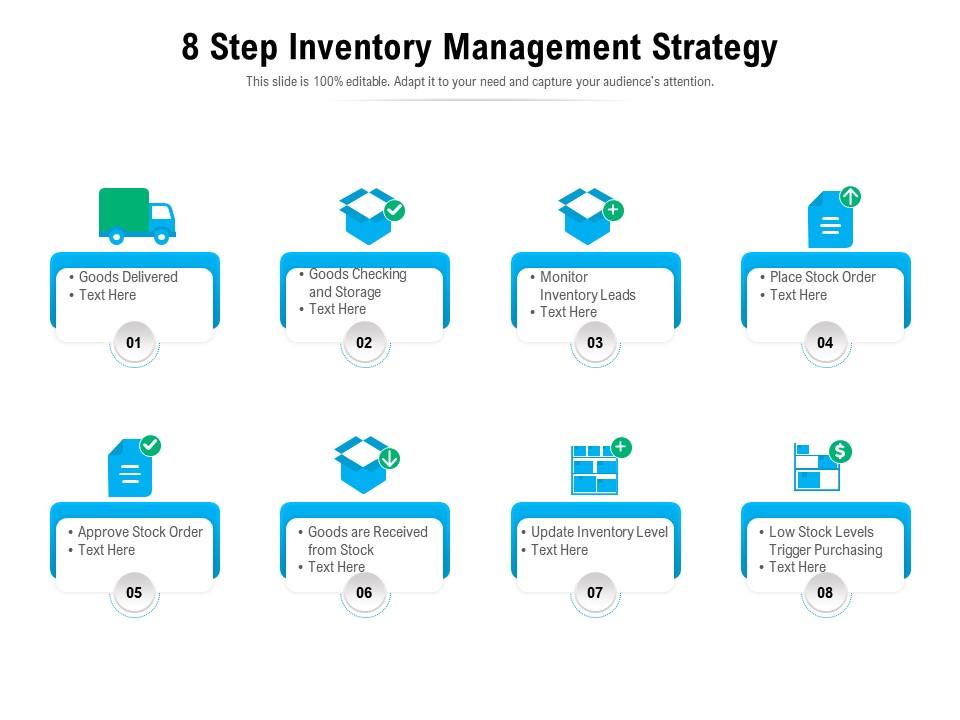

This involves having clear processes for receiving, storing, picking, packing, and shipping. It means having well-trained staff who understand the importance of accuracy and efficiency. It’s like having a well-choreographed dance routine. Everyone knows their steps, the music is playing, and the performance is seamless. When one person misses a step, the whole thing can get a little chaotic, can’t it?

The strategy should also embrace continuous improvement. The world changes, customer demands shift, and new technologies emerge. What worked perfectly last year might be outdated today. So, an effective strategy is one that is reviewed, analyzed, and adapted regularly. It’s like checking your car tires periodically for wear and tear, or updating your phone’s operating system. You do it to ensure everything keeps running smoothly and safely.

The Bottom Line: Less Stress, More Success

At the end of the day, a good operations strategy for inventory management should make your life easier. It should reduce those frantic searches for lost items, minimize those gut-wrenching moments of realizing you’re out of stock, and eliminate the financial drain of holding onto inventory that’s gathering dust.

It's about having peace of mind. It's about knowing that when a customer asks for something, you can deliver. It's about running your business like a well-oiled machine, rather than a chaotic junk drawer. And who doesn't want a little less chaos and a little more success? So, let's aim for that magical "just enough," keep our inventory systems singing, and maybe, just maybe, we’ll finally get that perfectly organized pantry. Or at least, we’ll know exactly where those pickled beets are hiding.