29 Cfr 1910 120 Requires Employers To Do What

Hey there, friend! So, you’ve probably stumbled upon this whole “29 CFR 1910.120” thing and thought, “What in the heck is that?” No worries, I’m here to break it down for you in a way that won’t put you to sleep. Think of me as your friendly neighborhood OSHA whisperer, minus the hazmat suit. (Though, depending on your job, maybe you are wearing one!) Let’s dive into this official-sounding jargon and see what it actually means for employers. It’s not as scary as it sounds, I promise! We’re talking about keeping people safe, and who doesn’t love that? It's all about making sure workplaces aren't secretly turning into a scene from a disaster movie. And let's be honest, some jobs do get pretty dramatic.

So, what’s the big deal with 29 CFR 1910.120? Basically, it’s a set of rules from the Occupational Safety and Health Administration (OSHA) that focuses on something called hazardous waste operations and emergency response. Yep, you read that right. Hazardous waste. Sounds… fun? Maybe not the most thrilling topic at a party, but super important if your work involves anything even remotely gooey, toxic, or prone to spontaneous combustion. It's like the universe's way of saying, "Hey, if you're messing with potentially dangerous stuff, you better have a plan!"

Let's Get Down to Brass Tacks: What Does It Actually Require?

Alright, let’s ditch the legal mumbo jumbo and talk turkey. This regulation is basically an employer’s “what to do when things go wrong with dangerous stuff” manual. It’s not just about preventing accidents, though that’s a huge part of it. It’s also about what to do when, despite best efforts, something does go wrong. Think of it like having a fire extinguisher. You hope you never need it, but boy, are you glad it's there when you do!

At its core, 29 CFR 1910.120 requires employers to implement comprehensive safety and health programs for workers who are involved in cleaning up hazardous waste or responding to hazardous substance emergencies. This isn't just a casual suggestion, folks. This is a legal mandate. So, if your job involves dealing with anything from a leaky chemical drum to a major industrial spill, your employer needs to be on top of this. No slacking allowed!

The Nitty-Gritty: Specific Responsibilities

Now, let’s get a little more specific. What does “comprehensive safety and health program” actually look like? It’s not just about handing out hard hats and saying, “Good luck!” This regulation dives deep into a few key areas. Think of it as layers of protection, like a really, really good onion. But hopefully, without the tear-jerking.

1. Site Characterization and Analysis: Know What You're Dealing With!

First off, employers have to be detectives. They need to figure out what exactly is lurking at the site. Is it just a little bit of spilled coffee, or is it something that could melt your shoes off? This means conducting thorough site characterization and analysis. They need to identify the hazards present, the potential risks, and the extent of contamination. It’s like reading the ingredients list on a questionable snack. You really want to know what you’re putting into your body… or your workplace!

This involves things like:

- Sampling and testing: Getting samples of the stuff and sending them off to a lab. No, you don’t get to lick it to find out what it is.

- Reviewing historical data: What happened at this place before? Did it used to be a glitter factory that went belly-up? That might be a clue.

- Consulting with experts: Sometimes, you just need a nerd with a clipboard to tell you what’s what.

The goal here is to have a solid understanding of the hazards before anyone even puts on a pair of gloves. Because, let’s face it, a surprise toxic goo spill is not my idea of a fun Tuesday.

2. Written Safety and Health Program: Paperwork Power!

Once they know what they’re dealing with, employers need to write it all down. And not just in a hastily scrawled sticky note. They need a written safety and health program. This is the blueprint for keeping everyone safe. It’s got to be detailed, specific, and accessible to all the workers. Think of it as the ultimate instruction manual for not getting hurt.

This program should cover:

- Organizational structure: Who’s in charge of what? Who’s the safety czar?

- Roles and responsibilities: What is each person expected to do (and not do)?

- Standard operating procedures (SOPs): Step-by-step guides for specific tasks. This is where the real “how-to” comes in.

- Emergency procedures: What to do if, you know, things go really sideways.

- Personal protective equipment (PPE) requirements: What gear do you need to wear? (Spoiler alert: it’s probably more than just your favorite t-shirt.)

- Monitoring and medical surveillance: How will they keep an eye on people's health and the environment?

Having a written plan is crucial. It ensures everyone is on the same page and reduces the chances of someone improvising a safety solution, which, as we all know, rarely ends well. Remember that time you tried to fix the leaky faucet with duct tape and it sprayed water across the entire kitchen? Yeah, that kind of improvisation.

3. Training: Because We Can’t All Be Superheroes!

This is a big one, folks. 29 CFR 1910.120 places a huge emphasis on training. Employers must ensure that all employees involved in hazardous waste operations receive adequate training. And “adequate” is the key word here. It’s not a one-and-done seminar. It’s ongoing and specific to the job.

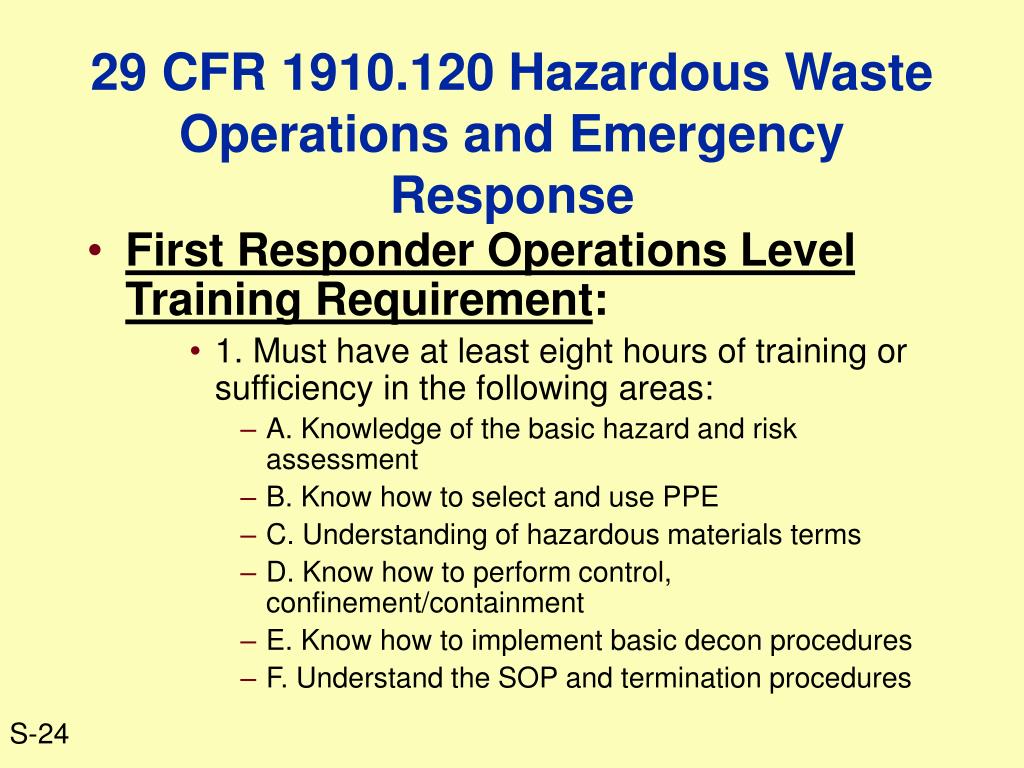

There are different levels of training depending on the worker's role:

- On-site managers and supervisors: They need a good chunk of training to understand the overall safety picture and how to manage the operation.

- Field workers (general site workers): These are the folks actually getting their hands dirty. They need comprehensive training on the hazards they’ll encounter and how to protect themselves. Think of it as becoming a certified “dangerous stuff handler.”

- Specialists and supervisors (off-site support): People who might be assisting from afar still need to know what’s going on.

- Emergency responders: These brave souls get the most intensive training because they’re the ones running towards the problem when everyone else is running away.

The training needs to cover things like hazard recognition, safe work practices, proper use of PPE, emergency procedures, and understanding the site-specific safety plan. It's basically equipping them with the knowledge and skills to be safe, savvy professionals. No one wants to be the guy who trips over a chemical barrel because they weren't told it was there, right? Or worse, the guy who opens the barrel out of curiosity. Please, don't be that guy.

4. Personal Protective Equipment (PPE): Suit Up!

This is where the cool (and sometimes not-so-cool) gear comes in. Employers are required to provide and ensure the proper use of personal protective equipment (PPE). This isn't just about comfort; it’s about creating a barrier between the worker and the hazard. Think of it as your personal force field against nasty chemicals.

Depending on the hazards identified, PPE can include things like:

- Chemical-resistant gloves: To protect those precious hands that probably do a lot of typing (or, you know, important stuff).

- Safety goggles and face shields: To keep errant splashes and flying debris out of your eyes. Nobody wants an impromptu eye-exam with acid.

- Respirators: To filter out harmful fumes and particles. Because breathing in weird industrial smells is generally not a good idea.

- Protective clothing: Coveralls, aprons, suits – whatever it takes to keep the nasty stuff off your skin and regular clothes.

- Safety footwear: To protect your feet from falling objects and slippery surfaces.

And here’s the kicker: it’s not enough to just provide the PPE. Employers need to make sure it’s properly fitted, maintained, and used correctly. They also need to train workers on how to use it. Because a mask is only useful if you actually, you know, wear it over your nose and mouth. It’s like buying a really fancy umbrella and then leaving it in your car during a downpour. Frustrating, right?

5. Medical Surveillance: Keeping an Eye on Your Health

When you’re dealing with hazardous substances, it’s important to keep tabs on how the exposure might be affecting your body. This is where medical surveillance comes in. Employers might need to implement a program that includes:

- Pre-assignment medical examinations: To get a baseline of your health before you start working with hazardous materials.

- Periodic medical examinations: Regular check-ups to monitor for any potential health effects related to your work.

- Post-exposure medical evaluations: If there’s a suspected exposure incident, a medical evaluation is crucial.

- Medical recordkeeping: Keeping detailed records of all medical findings.

This is all about being proactive. It’s like getting an oil change for your car – you do it regularly to prevent bigger problems down the line. And your body is way more important than a car, so this medical stuff is seriously important!

6. Emergency Response Plan: When Disaster Strikes!

Let’s face it, sometimes accidents happen, and emergencies are unavoidable. That’s why 29 CFR 1910.120 mandates a robust emergency response plan. This isn’t just a suggestion; it’s a critical component of keeping people safe.

This plan needs to cover:

- Procedures for different types of emergencies: Fires, spills, explosions – you name it, the plan should address it.

- Communication protocols: How will everyone communicate during an emergency? Who calls whom?

- Evacuation procedures: How will people get to safety? Where will they go?

- Roles and responsibilities of emergency responders: Who does what when the alarm sounds?

- Decontamination procedures: How will people and equipment be cleaned up after an incident?

- Coordination with external agencies: How will they work with local fire departments, HAZMAT teams, etc.?

Think of it as a well-rehearsed play. Everyone knows their lines, their cues, and their exit strategies. The better the plan, the smoother (or at least, less chaotic) the response will be. And in an emergency, less chaos is a beautiful thing.

7. Decontamination: Getting Clean After Getting Dirty

After dealing with hazardous waste or responding to an incident, decontamination is a super important step. It’s all about preventing the spread of contamination. This involves established procedures for cleaning workers, equipment, and even vehicles that have been exposed to hazardous substances.

This might include:

- Designated decontamination areas: Specific zones where this cleanup happens.

- Decontamination solutions: The right stuff to wash away the nasties.

- Waste disposal procedures: How to safely get rid of the contaminated materials.

It’s like showering after a muddy obstacle course. You have to get the mud off so you don’t track it everywhere. And in this case, it’s not just mud; it’s potentially harmful chemicals.

8. Site Control: Keeping Track of Who's Where

Finally, there’s the whole issue of site control. Employers need to implement procedures to control access to hazardous waste sites. This means making sure only authorized personnel are in the danger zone. It’s like a VIP section, but instead of fancy drinks, you get… well, you get to avoid getting sick.

This involves:

- Establishing exclusion zones: Clearly marking off areas where hazards are present.

- Setting up decontamination corridors: As we just talked about!

- Implementing buddy systems: Making sure no one wanders off alone into the unknown.

- Keeping accurate records of personnel on site: Knowing who is where and when.

Basically, it’s about managing the flow of people and preventing unauthorized entry into potentially dangerous areas. No surprise visitors allowed in the toxic zone!

Why Does All This Matter?

So, why go through all this fuss? It’s pretty simple, really. 29 CFR 1910.120 exists to protect people. It’s about preventing injuries, illnesses, and even fatalities. When employers follow these regulations, they are creating a safer environment for their workers. They are showing that they value their employees’ well-being. And that’s a pretty awesome thing, right?

Think about it: when you go to work, you want to come home in the same condition you left. This regulation is a huge step in making sure that happens, especially in industries that inherently carry more risk. It’s about making sure that a job that involves hazardous materials doesn’t have to be a death sentence. It's about ensuring that going home with a paycheck doesn't also mean going home with a mysterious rash or worse.

It also helps employers by reducing the risk of lawsuits, workers’ compensation claims, and hefty fines from OSHA. So, it’s a win-win! A safer workplace benefits everyone. It fosters trust, improves morale, and ultimately, leads to a more productive and positive work environment. Who knew that a bunch of legal regulations could actually be a good thing?

The Bottom Line

So, there you have it! 29 CFR 1910.120 basically tells employers: "If you're dealing with hazardous waste or emergencies involving dangerous stuff, you need to have a solid plan, train your people, give them the right gear, keep an eye on their health, and be ready to respond if things go south." It’s about being prepared, being responsible, and most importantly, being safe.

While it might sound like a lot of technical jargon, at its heart, this regulation is about caring for people. It’s about ensuring that those who perform difficult and potentially dangerous jobs do so with the highest level of protection. So, the next time you hear about 29 CFR 1910.120, don't run for the hills. Instead, think of it as a testament to the fact that we, as a society, are working hard to make sure that even the grittiest jobs can be done safely and with dignity. And that, my friend, is something to smile about!